Corralling and Trailering Cattle: Using a Drone

#bfrdpwy #aginternship #RightRisk

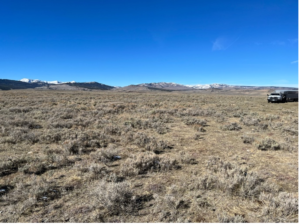

This week the weather began to get colder with snow finally falling up in the mountains; our team was excited to see the weather come. There is a term, the “white rider”, that means the accumulation of snow will pull the cattle down to the lower elevations and out of thick timber, making them easier to location and move. Even with the use of drones, finding cattle in the high country can be difficult, though cattle tend to leave a trail behind that doesn’t take an expert tracker to identify. Even so, a small percentage of the herd likes to find an isolated spot, much like elk, and will stay there until they are pushed out by weather, a predator, or a cowboy.

One day we found a cow/calf pair and a calf grazing in the open forest on a steep incline surrounded by gnarly terrain. It would have been a half day ride on horseback to get into a position that would enable us to drive the cattle down; we opted to try the drone. The thinking was if we could get atop of the cattle, and apply the right pressure, we could utilize the terrain to our advantage. The only place the cattle could go would be down into the draw that led to the valley floor. The tricky part was getting the drone in the right position.

You can only fly a drone 400 feet above the point of takeoff, per FAA rules, giving an operator significant limitation in rugged terrain. In this case, our elevation was significantly lower than the position of the cattle and we lacked a range finder, or adequate maps, to calculate the elevation difference. When flying a drone, you need to worry about the elevation difference between you and the target, as well as the height of the canopy (trees, shrubs, etc.) in the flight area. The clearing was surrounded on three sides with thick pine trees and with the elevation difference, the ingress route of the drone would be tricky. As they say on the ranch, it was “time to cowboy up!”

The flight pattern had to be just right to prevent the cattle from scattering back into the timber. In quick consultation with the other two senior team members, the agreed approach was to fly the drone into the target area from the top of the ridgeline and drop down below the canopy into the clearing above where the cattle were grazing. The drone was launched and piloted to the preplanned ingress route. Once the drone was in place, I utilized the onboard camera to assess the area for potential obstacles and was able to drop the drone onto the ridgeline above the cattle. This placed the drone into the appropriate angle, applying appropriate pressure to get the cows to move and in the correct direction, as well as protect against their escape (squirting) into the high country. With moving the drone back-and-forth, near the cattle, they began to respond and headed down the draw. Fifteen minutes later, they were down on the valley floor crossing over the stream bed. Riders mounted and trailed the cattle off to the designated loading point. As the riders trailed, I flew the drone back, collected the gear and drove the stock trailer to the allotment entrance (the loading point) and began the setup for the field bud box.

Setting up a bud box is done by parking the truck and trailer parallel to, and 5 feet from the fence at a 5-degree angle. Three panels are used, in conjunction with the trailer, to create the box and alley. One end of a panel is attached to the side of the trailer, the side farthest from fence with the trailer door hinges. Another panel is attached to the end of the first at a 90 degree towards and ending at the fence. The remaining panel is attached to the end of the second panel up against the fence. This creates the box; the truck and trailer create the alley.

There are critical tips to setup and loading that help ensure a smooth process; a few are listed here:

- Have the third panel placed to where it can swing next to and be tied to the trailer once the cattle enter the box; the key is to test it prior to loading

- Make sure the ropes for tying the panel gate are hanging off the trailer to allow for a quick grab and tie

- The trailer door should be tied to the first panel in the open position in a way that the rope can be easily be removed, allowing the door to be closed as fast as possible

- Be sure to tie all panels at two points of contact (high and low), to each other, to the fence, and to the trailer

- Look inside the trailer to ensure there are no obstacles that would cause the lead cows to turn around

- Have the cattle enter the alley and the box with as little pressure as possible

- Do not try to load too many animals at a time

- Keep the dogs back and away from the loading area, they add too much pressure and get the cattle agitated

- Do not apply a lot of pressure until the third gate is tied and secured to the trailer

I’ve loaded cattle enough times with different senior hands that we have the process down to a science. If we miss one of the setup steps or apply too much pressure, there will be a wreck, guaranteed. Team members should discuss setup expectations prior to starting a trail and loading sequence. Figuring out these details during loading will potentially cause a wreck and injure a team member or the cattle. As the senior hands often say, there is a fine line between applying the right pressure versus too much and that can only be learned by doing it. Plus, every situation is different and not all cows are the same. When everything goes right, the cattle will walk right into the trailer with very little pressure, quiet as can be. These steps are not my own, but were learned from the collective input of the senior hands and ranch owner. George Kahrl (Owner), Tyler Farrenbaugh (Manager), Dino Stauffer (Senior Hand), Dylan Marsh (Senior Hand) have over 100 years of combined ranching experience between them and have the scars to prove it. In fact, none of the lessons learned are not without the input and guidance of one of these or former team members Richard & Wanda Griffin – such fine people. All of whom have my respect and admiration for taking the time with this green horn.

The entire operation presented was an excellent example of communicating as a team to create an ad hoc plan to develop a creative solution. Team members were able to quickly discuss concerns, approaches, and determine an overall plan. In just a matter of minutes, a drone was in the air and riders mounted setting off to collect the cows. The right questions were asked, expectations were set, and the operation was completed without any hiccups. Smooth as can

be. As the A-Team character Hannibal Smith said, “I love it when a plan comes together”.

Submitted by: Tim Bauer

Edits by: GrowinG Internship Team